MSFT-1

Tensile Load Capacity-5000 kg

Flexural Load Capacity–225 kg

We work in closed collaboration with our customers to optimize product designs that provide sustainable value to them; this is achieved through a constant focus on our R&D efforts.

We are committed to provide total customer satisfaction through our quality products by continuously updating our technical competence and services.

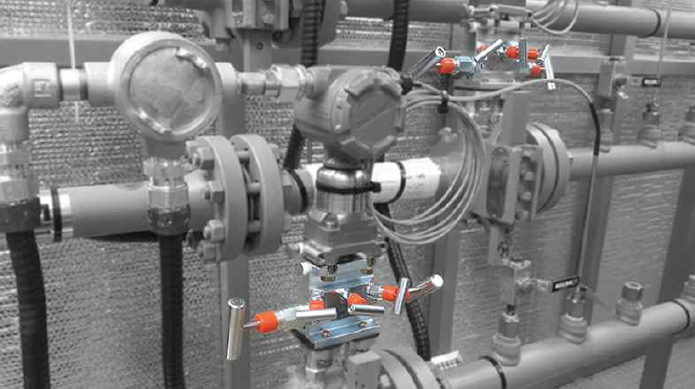

Tests are carried out in accordance with SP 99, ASTM F 1387 and as per Design Standards ANSI B 31.1/31.2/31.3 Secon VIII, ASME - B- 31.3, ANSI - B - 2.1/1.1.

Over 1.5 million Valves and Manifolds and Over 1 million Fluid connectors installed.

A true testimony to our Quality, Customer satisfaction and Commitment to this market

MSFT-1

Tensile Load Capacity-5000 kg

Flexural Load Capacity–225 kg

msft-3

Range: 0°C to 1000°C

msft-06 EB 01

Tensile Load Capacity-5000 kg

msft-02

Range: 0°C to 1000°C

Range CC-01: 20°C-40°C,

54-99% RH

Range CC-02: 20°C - 40°C,

40-70% RH

msft-08

FR 01

Very High Pressure 60,000 psi Hydro Pneumatic Pump for all types of tests and certification.

© 2021 All Rights Reserved by Indiainternets